- Home

- Services

- Conceptual Design

- Digital Twin Simulation & Emulation

- Manufacturing Flow Design

- Maveneer WxS™

- MavenSHIELD™

- Operational Assessment

- Operational Augmentation

- Process Standardization & Compliance

- Retrofit Design & Modernization

- Supply Chain & Inventory Management

- Supply Chain Network Analysis & Optimization

- Systems Integration

- Warehouse Optimization & Performance Monitoring

- WMS & WES Selection & Strategy

- Workforce Training & Development

- 3D Integrated Modeling

- Industries

- Solutions

- Autostore

- Automated Print and Apply

- Automation as a Service

- Autonomous Mobile Robots

- Automated Guided Vehicles

- Automated Storage & Retrieval Systems (AS/RS)

- Control System Integration

- Conveyor Systems

- Packaging Automation

- Palletizing

- Depalletizing

- Sortation Systems

- Microfulfillment

- Omnichannel Fulfillment

- eCommerce Fulfillment

- Order Picking

- Robotic Vision Systems

- Warehouse Execution Systems

- Warehouse Storage Racking Solutions

- Resources

- Company

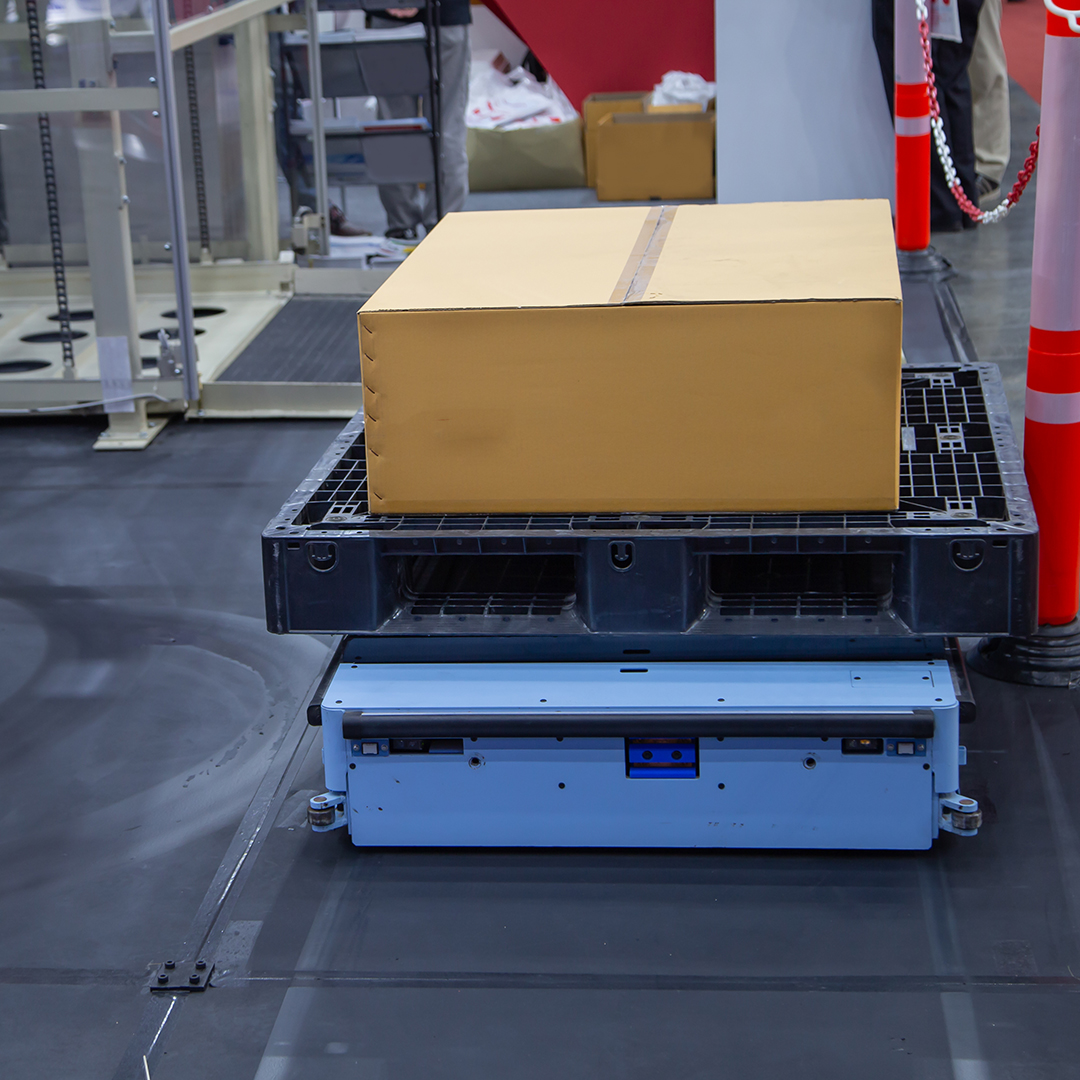

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are self-navigating machines utilized in warehouses to automate material handling and logistics operations, improving efficiency and reducing manual labor.

Maveneer partners with trusted manufacturers to bring the benefits of automation to your warehouse:

KEY TAKEAWAYS

Key Characteristics:

- Autonomy: AMRs make decisions and navigate without human intervention, unlike AGVs that follow tracks.

- Flexibility: They can move freely, adapt to changing conditions, and avoid obstacles.

- Advanced Technology: AMRs use sensors like cameras and LIDAR, along with AI and machine learning for navigation.

How AMRs Work:

- Sensing: Detect surroundings and obstacles.

- Path Planning:Calculate optimal routes.

- Real-time Adaptation: Dynamically adjust routes.

- Task Execution: Handle transport, picking, sorting, and more.

Autonomous Mobile Robots: Applications & Benefits

What are Autonomous Mobile Robots (AMRs)?

At its core, an Autonomous Mobile Robot (AMR) is a robotic system equipped with sensors, navigation technology, and decision-making algorithms that allow it to operate without human intervention in various environments. Unlike traditional robots that follow strict programming, AMRs can adapt in real-time, making them valuable in various industries.

Applications of AMRs

Autonomous Mobile Robots (AMRs) have use cases in a wide variety of industries. Their adaptability has made them invaluable in industries such as:

- Warehousing and Logistics

- E-Commerce Order Fulfillment

- Manufacturing and Assembly

- Healthcare and Hospital Logistics

- Agriculture and Field Monitoring

- Retail and Customer Service

- Security and Surveillance

AMRs represent a significant shift in automation. They are designed to augment human capabilities, improve efficiency, and streamline operations across industries. By autonomously navigating complex environments and performing tasks precisely, they reduce manual labor, enhance safety, and offer cost-effective solutions.

AMRs are use frequently in warehouse operations, moving goods, picking orders, and managing inventory autonomously. They can also seamlessly scale up or down to meet the demands of the business. While we will focus most of our time on this use case, let's explore some other practical use cases of Autonomous Mobile Robots:

E-Commerce Order Fulfillment

In e-commerce, AMRs expedite order processing, ensuring accurate and swift deliveries. By minimizing picking and replenishment time, they are pivotal in maximizing productivity. Because they are adjustable in real time, they are well suited to act as a sortation mechanism to properly aggregate multiple lines for an order, eliminating the need for manual sortation.

Manufacturing and Assembly Line Efficiency

Manufacturing benefits from AMRs for tasks like material handling and quality control, boosting productivity. AMR technology has also evolved to handle products and environments that are unsafe for humans. This includes heavy, oddly shaped, and hazardous materials, which can be transported in a variety of methods including cartons, shelves, and pallets.

Healthcare and Hospital Logistics

AMRs enhance healthcare logistics, delivering medications, managing inventory, and transporting medical equipment, freeing up healthcare professionals to perform more relevant tasks. By automating the picking and delivery, they can also provide high confidence verifications of product delivery, ensuring that customers receive the correct medication.

Agriculture and Field Monitoring

In agriculture, AMRs monitor crops, perform tasks like planting and harvesting, optimizing yield and reducing manual labor. By utilizing other technologies, such as vision systems, soil monitors, humidity sensors, and LIDAR they are well equipped to analyze and provide useful feedback to human operators on best practices to improve yield.

Retail and Customer Service

Retail stores use AMRs for tasks like shelf restocking and inventory management, improving the shopping experience and ensuring shelves remain stocked for customers. They are even utilized for food and beverage delivery in restaurants, improving customer experiences. Because of their advanced navigation and sensing systems, they are typically safe to operate around the general population and can adapt to changing environments and configurations.

Security and Surveillance

AMRs enhance security through tasks such as patrolling areas and providing real-time video surveillance to offer better coverage to sensitive areas. Integration with security systems means AMRs can adapt to identified security concerns, and continuously monitor and record observations without the need for downtime or interruptions.

How do Autonomous Mobile Robots Work?

To understand AMRs better, let's examine their operational principles:

Sensor Technologies and Perception Systems: AMRs rely on sensors like LiDAR, cameras, lasers, and ultrasonic sensors to detect obstacles and navigate their environment effectively. Continuous monitoring and feedback from these sensors provides a safe and reliable work environment for the AMRs and any operators working near them.

Navigation and Localization Techniques: AMRs use navigation techniques, including Simultaneous Localization and Mapping (SLAM) algorithms, to create maps of their surroundings and determine their position accurately. They can adapt and react to changes in their environment, providing a robust solution to an ever changing work environment.

Decision-Making Algorithms for Autonomy: AMRs use decision-making algorithms to process sensor data, analyze it through AI, algorithms, and machine learning models, and make autonomous decisions for navigation and task completion.

Benefits & Challenges of Autonomous Mobile Robots

Benefits of AMR Implementation

Improved Efficiency and Productivity: AMRs streamline operations, reduce errors, and work continuously, leading to efficiency and productivity gains.

Enhanced Workplace Safety and Risk Reduction: By handling dangerous or repetitive tasks, AMRs contribute to workplace safety and reduce the risk of accidents. Advancements in capabilities continue to add uses for AMRs and avoidance of risk to operators.

Cost Savings and Labor Optimization: Reducing labor costs and optimizing resources make AMRs a cost-effective solution for businesses.

Real-time Data Collection and Analytics: AMRs collect valuable data during operations and react to changing needs, enabling data-driven decisions and process optimization.

Scalability and Adaptability in Dynamic Environments: AMRs are scalable and adaptable, suitable for changing work environments and future growth. They are commonly implemented in Automation as a Service (AaaS) providers, offering scalable and cost effective solutions for changing business needs.

Challenges of AMR Implementation

Despite their advantages, AMRs pose challenges and considerations:

Navigating Complex Environments: Navigating complex environments remains a challenge for AMRs, requiring ongoing technological advancements.

Interoperability with Existing Systems: Integrating AMRs with existing systems and workflows can be complex and requires careful planning.

Security and Privacy Concerns: Addressing security and privacy concerns is essential to protect data and prevent misuse.

Workforce Collaboration and Training: Effective collaboration with human workers and proper training are crucial to maximize the potential of AMRs and smooth change management within your business.

Maintenance and Reliability: Maintaining the operational reliability of AMRs presents a significant challenge. Ensuring continuous uptime requires robust maintenance protocols and quick response times to address technical issues promptly. Proactive monitoring and regular servicing are essential to minimize disruptions in automated operations.

Choosing the Right Autonomous Mobile Robots (AMRs)

When deciding which AMR to choose, there are several key considerations that should guide your decision-making process.

- Assess specific warehouse needs and operations for automation suitability.

- Consider inventory type, size, and warehouse layout.

- Ensure compatibility with existing systems and infrastructure.

- Choose a reliable AMR provider with maintenance and support services.

- Prioritize workforce training for effective AMR collaboration.

By thoughtfully considering these elements before you begin implementing this into your warehouse, you can pave the way for a successful AMR implementation, enhancing efficiency and productivity in your warehouse.

Conclusion

Autonomous Mobile Robots are revolutionizing industries with their versatility, efficiency, and adaptability. They collaborate with humans, enhance safety, reduce costs, and collect valuable data, making them indispensable in the evolving landscape of automation. As we move forward, the integration of AMRs into various industries will continue to drive innovation and reshape how we work and live.

Ready to explore the potential of Autonomous Mobile Robots for your business? Contact Maveneer today to embark on the journey of innovation and automation.

MAVENEER IS READY TO HELP YOU

SELECT, MANAGE, DESIGN, AND IMPLEMENT AUTONOMOUS MOBILE ROBOTS IN YOUR WAREHOUSE

©2026 Maveneer, LLC All Rights Reserved. Sitemap.