What Is Warehouse Automation?

Warehouse automation is the use of digital and physical technology, material handling systems, robotics, and other technologies to automate various operations within a warehouse such as inventory management, order fulfillment and intralogistics. This article will explore the types, benefits, challenges, costs, and best practices for designing and implementing warehouse automation systems and explain how they are rapidly transforming the way warehouses operate in today’s modern economy.

Why is Warehouse Automation Important?

Implementing warehouse automation helps address many common challenges that warehouses face, including:

- High labor costs

- Poor productivity

- Labor shortages and high turnover rates

- Inaccurate inventory and ability to track inventory in real-time

- Low cubic utilization within a truck or shipping containers, resulting in higher transportation costs

- Material flow issues and bottlenecks

- Poor use of space and storage density

- Inability to meet customer demands and service level time frames

- Poor processing efficiency

- Lack of resiliency to changing business environments and order composition

- Inability to keep up with sales demand

- Safety and ergonomic issues

By implementing warehouse automation, companies can address these challenges and improve their warehouse operation and overall supply chain efficiency and resiliency.

Categories of Warehouse Automation

There are several high-level categories of warehouse automation that can be considered when designing and implementing automation within a warehouse:

1. Material Handling Equipment (MHE)/Material Handling Systems (MHS)

This category of warehouse automation includes systems that can move material and transport goods within a warehouse, reducing labor content associated with those functions. These systems include:

- Conveyor Systems

- Routing and Shipping Sortation Systems

- Unit Sortation

- Automated Storage Retrieval Systems (ASRS)

- Goods to Person (GTP) Systems

- Automated Guided Vehicles (AGVs)

2. Inventory management automation

This category of systems enables greater inventory accuracy and more sophisticated operations through better use of data, enhanced location management, and reduced errors. It includes:

- Warehouse Management systems (WMS)

- Automatic Identification and Data Capture (AIDC)

- Barcode Scanning Technology

- Radio Frequency Identification (RFID)

- Vision Inspection Systems

3. Order Fulfillment Automation

This category of systems can reduce labor content, increase order accuracy, and enhance consumer experience, and includes technologies such as:

- Goods to Person Systems (GtP)

- Autonomous Mobile Robots (AMRs)

- Light Directed Picking

- Robotic Picking

- Automated Print and Apply (PandA)

- Automated Pack Slip Insertion

- Print On-Demand Technologies

4. Data Analytics, Artificial Intelligence, Data Science, and Digital Warehouse Optimization

This category includes software tools, algorithms, and visualization systems that collect and analyze real-time transactional data throughout the entire operation to optimize warehouse operations such as material flow patterns, inventory levels and utilization, labor balancing, fulfillment cycle times, and real-time coordination with outbound shipping schedules. Warehouse Execution Systems (WES), often span multiple categories of warehouse automation including this one.

5. Custom Automation

This category of automation provides solutions to problems where a standard option doesn’t exist, and a custom-engineered solution specifically designed to meet the unique needs of a business is warranted and cost-justifiable. Businesses should understand that not every solution provider is positioned well to build and implement custom automation solutions.

By understanding these high-level categories of automation, businesses can increase their understanding of how each of these categories can positively impact their supply chain.

17 Types of Warehouse Automation Solutions

Now that we have a good understanding of the high-level categories of warehouse automation, the following is a more granular outline of physical warehouse automation. While we will dive more deeply into Inventory Management, Data Analytics, and Custom Automation categories in future blogs, this article will focus on Material Handling Equipment and Order Fulfillment categories:

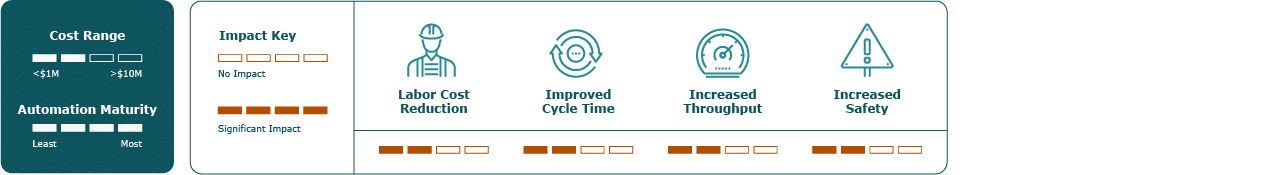

1. Conveyor Systems

Conveyor systems have many different applications inside and outside warehouse operations. Within distribution warehouses, conveyor systems can move pallets, boxes or cartons, totes, and sometimes discrete “eaches” throughout a warehouse. This movement reduces the labor associated with these tasks. Types of conveyor systems applicable to warehouse operations include:

- Pallet conveyor

- Zero pressure accumulation conveyor

- Minimum pressure accumulation conveyor

- Belted and roller transportation conveyor

- Live roller conveyor

- Line shaft conveyor

- Motorized drive roller

- Gravity conveyor

The top conveyor manufacturers include Dematic, Honeywell-Intelligrated, TGW, Hytrol, Daifuku, Itoh Denki, and Interroll. Each of these conveyor suppliers are capable of manufacturing multiple types of conveyors and can be considered for a variety of applications.

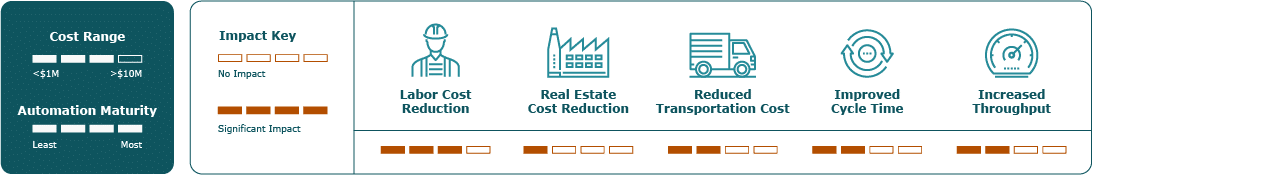

2. Sortation Systems (Routing and Shipping Sortation)

Sortation systems directly reduce the labor associated with sorting cartons, totes, or “eaches” in a warehouse operation. There are different types of sortation systems including:

- Linear sorters including sliding shoe sorters, narrow belt sorters (NBS), and pop-up wheel sorters

- Loop sorters such as cross belt sorters, tilt tray sorters, and bomb-bay sorters.

- Autonomous Mobile Robots (AMR) based sorters

The top manufacturers of sortation systems overlap quite significantly with the conveyor system manufacturers listed above, but also include additional suppliers such as Beumer, Crisplant, Korber, Ferag, and others.

3. Unit Sortation

Unit sortation is a means of handling individual units of an order, and often using the sortation system to sort individual units of an order or batch of orders. Loop sorters such as cross belt sorts, tilt tray sorters, and bomb-bay sorters can be used in this manner. Additionally, pocket sorters, also known as pouch sorters, can be deployed in this manner.

Unit sortation is a means of handling individual units of an order, and often using the sortation system to sort individual units of an order or batch of orders. Loop sorters such as cross belt sorts, tilt tray sorters, and bomb-bay sorters can be used in this manner. Additionally, pocket sorters, also known as pouch sorters, can be deployed in this manner.

Top manufacturers for this warehouse automation include SSI Schaefer, Dematic, Knapp, Ferag, Beumer, and others.

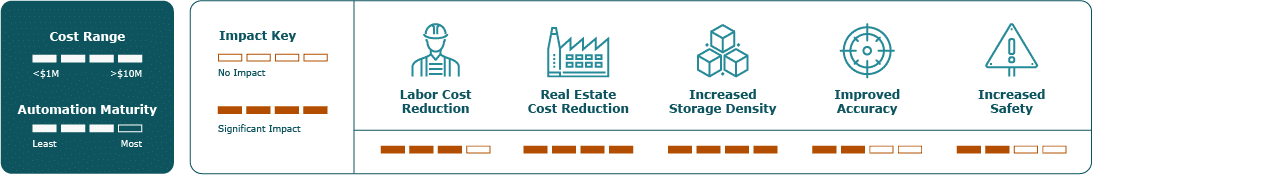

4. Automated Storage and Retrieval Systems (AS/RS)

Automated storage and retrieval systems are a broad category of warehouse automation that span many different storage mediums including pallets and pallet boards, referred to as “unit load” ASRS, and totes, bins, and cases, referred to as either mini-load ASRS or goods to person. ASRS removes labor content associated with finding and accessing inventory, i.e., time spent walking or driving, and can also greatly increase storage density. Unit load and mini-load ASRS are capable of supporting very tall building heights, drastically increasing storage density.

5. Goods to Person Systems (GtP)

Goods to person systems are a subcategory of ASRS but are noteworthy to call out on its own due to its maturity and rapidly increasing adoptability for order fulfillment warehouse automation.

There are many goods to person systems on the market including AutoStore, OPEX Perfect Pick and Infinity ASRS, Attabotics, Exotec SkyPod, Murata Machinery Ledger, SSI Schaefer SCS, Dematic Multi-Shuttle, Knapp OSR, Swisslog CarryPick, and Vanderlande Adapto.

Additionally, AGVs and AMRs can be applied in goods to person applications. Each of the GtP systems outlined above can reduce labor for order fulfillment and increase storage density.

6. Automated Guided Vehicles (AGV)

AGVs automate material movements throughout the warehouse by automatically transporting pallets, trolleys, or tooling within an operation. AGVs are a mature technology with a deep history in manufacturing. Historically, AGVs navigate by sensing an external system of magnets, reflectors, tape, or wire within its operating envelope.

7. Autonomous Mobile Robots (AMR)

AMRs, although like AGVs, are typically smaller than AGVs and contain more sophisticated navigation and routing capabilities. AMRs can be deployed in a wider range of applications ranging from discrete order picking, carton sortation, material delivery, and inventory inspection.

Some of the leading AMR suppliers on the market include HAI Robotics, Grey Orange, Geek+, Caja Robotics, and Invia Robotics.

8. Packaging Automation

Packaging automation encompasses a wide range of technologies spanning automated carton erectors, random height case sealers, cold seal machines, poly bagging machines, stretch wrapping and shrink-wrapping machines, and right sizing technology.

Right sizing technology effectively cuts or shrinks the shipping container around the order contents, thereby eliminating the need for void fill and optimizing the transportation costs with the smallest possible dim weight.

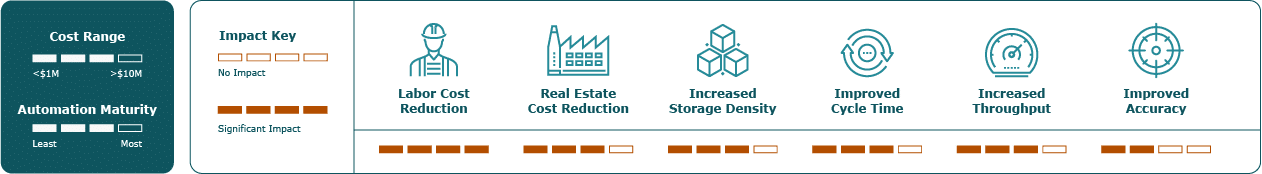

9. Robotic Picking

Robotic picking within a warehouse includes robotic case picking, layer picking (multiple cases on a single layer of a pallet), and robotic each picking. Using fixed robotic arms with a specialized end effector, robots can mechanically grip whatever object they need and place it on outgoing totes, containers, pallets, or other robots. Robotic vision systems combined with machine learning algorithms can greatly enhance the reliability and range of variability robotic picking can apply to.

Robotic picking eliminates nearly all the labor content associated with picking items in a warehouse.

10. Truck Loading and Truck Unloading

Unloading and loading trucks are fundamental to every warehouse operation. These manual and often ergonomically challenging tasks can be augmented with semi-automated options such as expandable flexible conveyors or telescopic conveyors to automatically convey cases out of or into trucks. Additionally, fully automated truck unloading and loading is a growing space, although far less mature than the semi-automated options on the market.

11. Robotic Palletizing and Depalletizing

Palletizing robots have the payload and reach required to build pallets or “depalletize” pallets automatically. This functionality can greatly improve worker safety, reduce labor costs, and especially in the case of layer picking, greatly increase throughput for high velocity case picking.

Palletizing robots have the payload and reach required to build pallets or “depalletize” pallets automatically. This functionality can greatly improve worker safety, reduce labor costs, and especially in the case of layer picking, greatly increase throughput for high velocity case picking.

12. Weight, Scan, and Dimensioning Systems

Weight, scan, and dimensioning systems are systems that replace the manual identification of an order carton’s barcodes, weight, and dimensions for ship manifest processes. Often these inputs are needed to calculate proper dim weight and costs, and can be used to rate shop and determine the lowest cost method of shipping.

These systems are typically placed in line on a conveyor system where cartons automatically convey across an in-motion scale, through a scan tunnel for automatic identification and data capture (AIDC), and pass under a dimensioning system to acquire the carton’s dimensions.

13. Automated Print and Apply (PandA)

Automated print and apply systems work in tandem with a WMS and or WES system, an upstream weight, scan, and dimensioning system, and place the shipping labels onto outgoing order cartons much faster than manual operations.

Automated print and apply can also be used to place other labels on cartons or eaches for value added services (VAS), special markers or identifiers, or any custom application.

14. Light-Directed Picking (Pick-to-Light and Put-to-Light)

Pick-to-Light

Put-to-Light

Light directed picking enables increased productivity and order accuracy by clearly identifying the location of interest in pick or put function in order fulfillment. This technology can be used on the face of inventory slots for picking directly from inventory locations. It can also be used at a put wall where cubbies are arranged with lights to help workers sort a batch of product down to discrete orders.

15. Automated Order Verification Systems

Automated order verification systems inspect each discrete unit within an order or order batch to ensure that the right item has been picked. This technology utilizes a combination of vision systems, barcode scanning, weighing, and other sensors to compare expected inventory to actuals to determine high confidence of order accuracy. This type of system prevents the wrong items from being shipped to the customer and is vital to high value and high regulatory settings such as pharmaceutical order fulfillment.

16. A-Frame Dispensers

A-frame dispensers are a technology that stores inventory in an A-shaped frame over the top of a conveyor. Discrete units are dispensed from individual cartridges that make up this frame directly onto the conveyor. A-frame dispensers can be used to automatically pick discrete orders or a batch of orders. They are typically deployed in high volume warehouses with small items that are compatible with the narrow cartridges and dispensing mechanisms. The pharmaceutical and cosmetic industries are the most likely industries to benefit from this technology.

17. Automated Order Consolidation Systems

Automated order consolidation systems overlap significantly with unit sortation systems, although there are some differences in that consolidation can be done via robotics, conveyors, or shuttles such as Opex’s Sure Sort technology. The purpose of the technology is to establish order integrity, consolidating all the contents of an order in one location, so that it can be packed and shipped out of the warehouse.

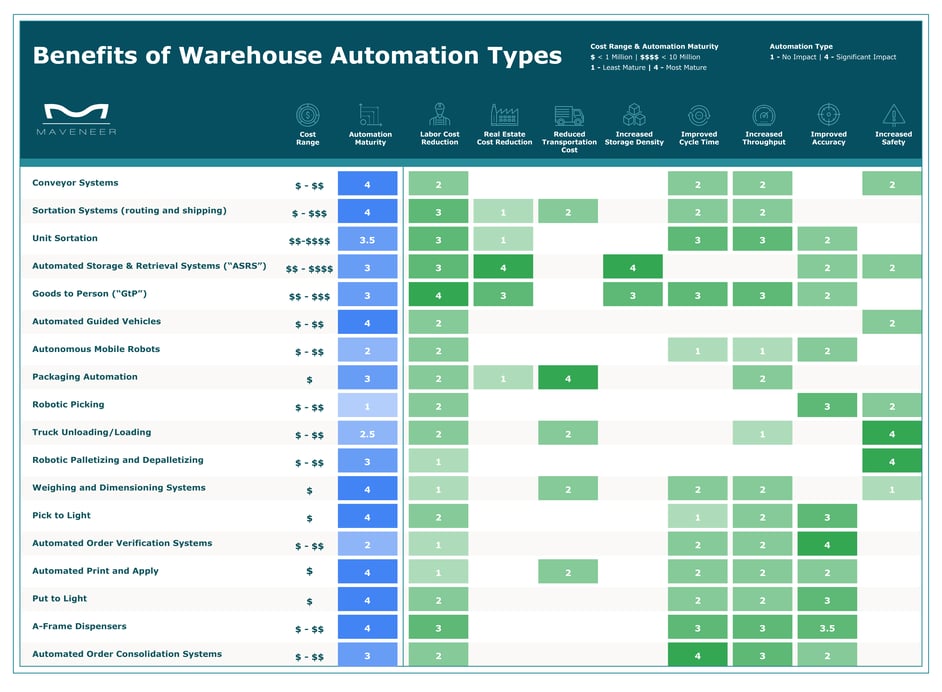

Warehouse Automation Types Comparison Table

Download the table here.

Benefits and Challenges of Warehouse Automation

What Are the Benefits of Warehouse Automation?

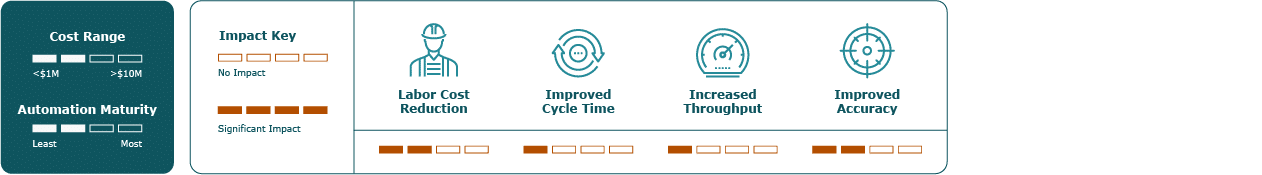

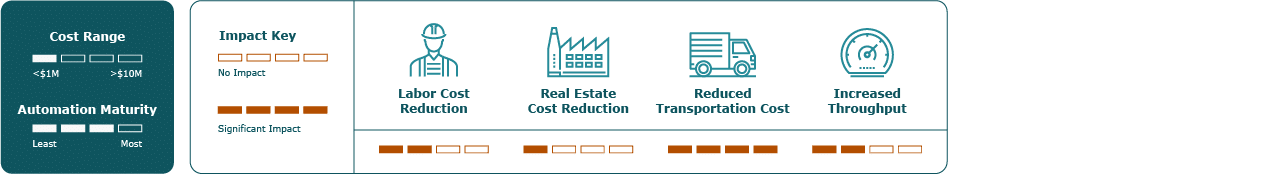

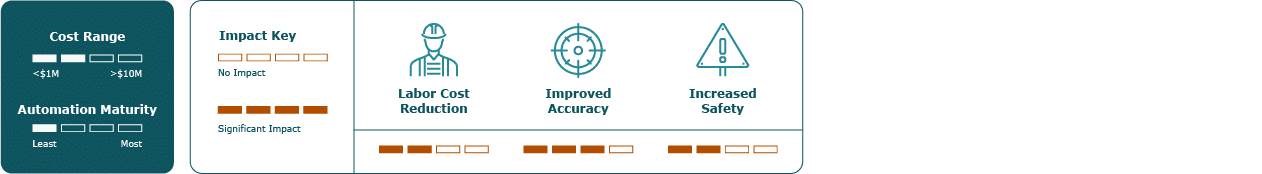

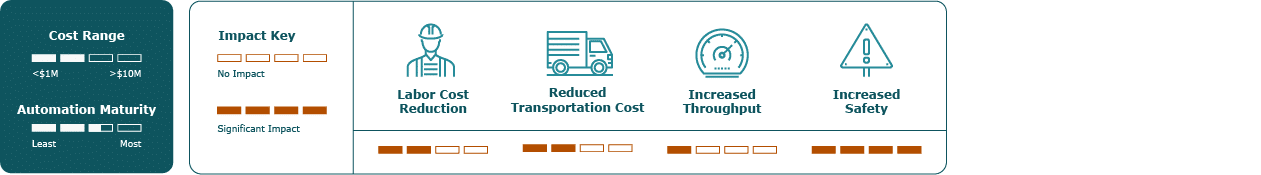

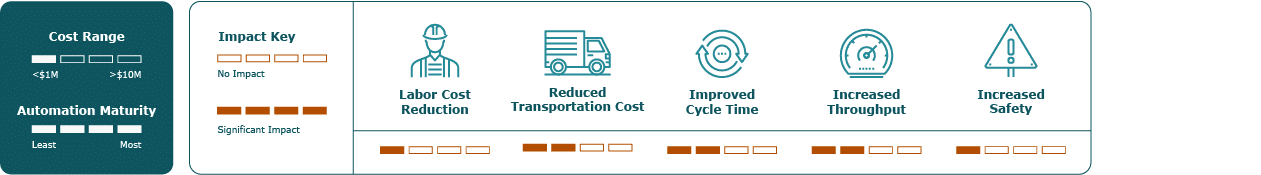

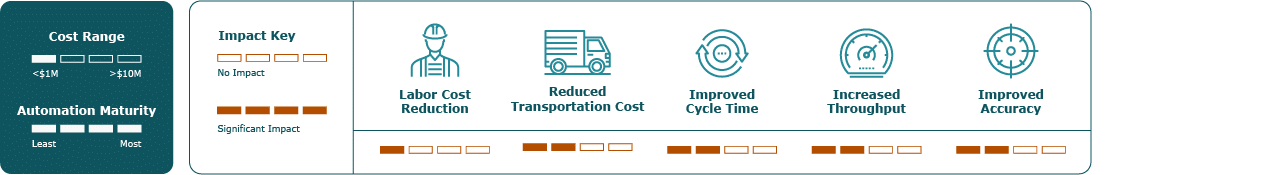

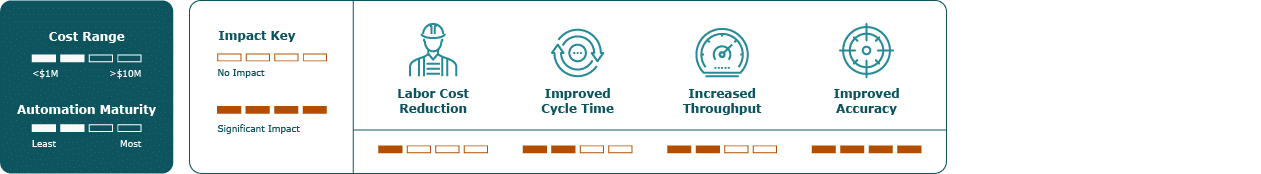

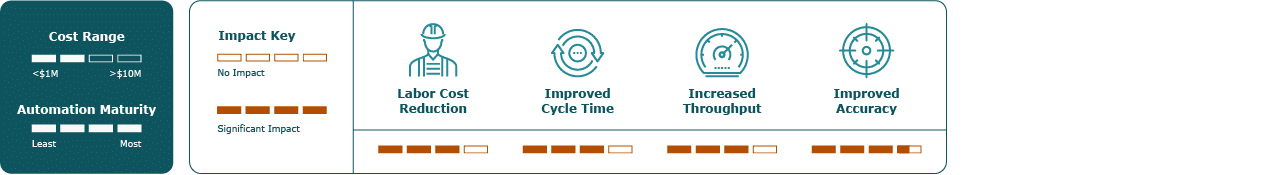

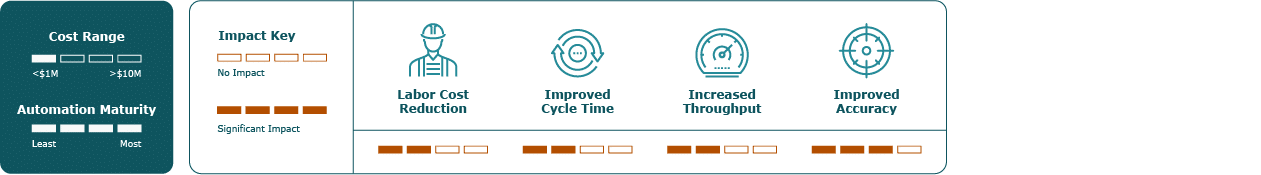

- Labor Cost Reduction

- Reducing labor costs is often the number one benefit, but not the only benefit, for financially justifying warehouse automation.

- Real Estate Cost Reduction

- Warehouse automation can increase storage density and reduce the square footage needed for a warehouse, thereby reducing real estate costs.

- Reduced Transportation Cost

- Certain types of warehouse automation can reduce package size, or increase the density of an outbound trailer, thereby decreasing the cost of transportation per cubic foot of product shipped.

- Increased Storage Density

- Increased storage density allows you to fit into less space, potentially allowing you to acquire smaller, less expensive buildings. It can also help reduce labor costs associated with finding and retrieving inventory in the order fulfillment process.

- Decreased Service Time To Customers

- Decreasing the time to pick, pack, ship, and deliver to customers is typically measured within an operational design as improved cycle time and or improved outbound throughput and can enable new sales and increase loyalty.

- Improved Accuracy

- Warehouse automation can improve both order accuracy and the accuracy of inventory stored within a warehouse.

- Increased Safety

- Repetitive tasks or picking items that are either too heavy or irregularly shaped can be replaced with warehouse automation thereby increasing safety.

- Supply Chain Resiliency

- The overall warehouse automation deployment within a facility can increase supply chain resiliency, making it less painful to absorb the inevitable unexpected impacts on your business.

What Are the Challenges Associated with Warehouse Automation?

While deploying warehouse automation unlocks significant value for most businesses, it’s not without challenges. Here are a few challenges associated with warehouse automation that you and your warehouse automation partner should proactively manage:

- Capital cost of warehouse automation can be significant. Significant financial benefits should be assessed to justify the investment in warehouse automation.

- Maturity of each type of warehouse automation varies drastically. Not every class of automation has been around as long as others and thus the reliability, resiliency, and support will differ.

- Catalogue solutions may have worked in prior applications or for the last project, but catalogue solutions aren’t necessarily optimized for your specific application, requirements, and objectives. Watch out for solution providers that are only interested in deploying solutions from within their portfolios.

- Significant planning horizons can be required, and often project teams are behind the curve, trying to catch up.

- Long lead times for certain types of warehouse automation can impact your overall schedule.

- Unexpected supply chain interruptions can quickly detour your detailed plans.

- Change management is important to consider and include in your project plan. Educating and training your personnel on the material changes that can result from implementing warehouse automation is necessary for success.

- Without a strong team, your warehouse automation may be designed or executed poorly.

Automating Your Warehouse

Which Warehouse Processes Can Be Automated?

Most distribution fulfillment warehouses consist of the following processes, each with a varying degree of viability for warehouse automation contingent on several factors:

| Process | Automatable

[1 – 4] |

Example Automation |

| Truck unloading | 2 | Robotic truck unloading |

| Receiving | 4 | Receiving sortation system |

| Put-away | 3 | Pallet put-away by AGV |

| Case picking | 4 | Auto pick by shuttle or mini-load ASRS |

| Each picking | 2 | Robotic each picking or A-frame dispensers |

| Replenishment | 3 | Shuttle system replenishment to back of carton flow |

| Order consolidation | 2 | Unit sortation or automated put wall |

| Packing | 3 | Poly baggers, right sizing machines, and document insertion |

| Shipping/manifesting | 4 | Automated print and apply |

| Truck loading | 2 | Robotic truck loader |

How Much Does It Cost to Automate Your Warehouse?

The cost of warehouse automation can vary substantially on several factors including complexity, size of the warehouse, storage capacity, throughput capabilities, and market maturity. It’s also important to understand the total cost of ownership, not just the upfront capital costs. Total lifetime cost of warehouse automation should consider:

- Upfront capital

- Initial spare parts

- Annual licensing costs

- Licensing associated with warehouse control systems and or warehouse execution systems are required to run the system

- Maintenance expenses

- Replacement spare parts

- Ongoing support expenses

- Other incremental operating expenses to support the automation such as specialized technicians or other roles, special materials that may be required for packaging automation or batteries, etc.

How to Automate Your Warehouse

Implementing warehouse automation within your facility should follow a process that (i) seeks to meet your business and operational requirements, (ii) satisfies future growth and compositional changes to the business, and (iii) provides a compelling return on investment.

The overall project lifecycle of implementing warehouse automation should be led and managed by competent professionals with expertise in operational design, industrial automation, systems integration, construction, and risk management. A recommended path to automate your warehouse is found below in an example project life cycle:

Step 1: Strategy and Feasibility

- Determine consumer needs and service levels

- Determine the role and purpose of each facility within the network

- Answer network wide questions such as new facility expansion, consolidation, or relocation

- Determine product category expansion or other compositional changes to the business

- Consider merger and acquisition (M&A) opportunities or requirements

Step 2: Conceptual Operations Design

- Analyze historical data

- Model future state growth and business composition

- Define business and operational requirements

- Evaluate process and warehouse automation alternatives

- Assess return on investment and develop an overall business case

- Develop high level implementation road map

Step 3: Detail Design

- Simulate the design

- Evaluate and select suppliers

- Reconcile the overall design with Warehouse Management System functionality and other IT systems

- Track net changes to scope, cost and schedule

- Develop test plans and acceptance criteria

Step 4: Implementation

- Prepare and issue contracts

- Procure all materials

- Mechanically and electrically install the system

- Commission the system

- Perform operational and maintenance training

Step 4: Acceptance and Turnover

- Test the equipment according to the test plans

- Complete unit testing, operational readiness testing, and peak and volume run-time testing.

- System acceptance and turnover

- Go-live!

- Monitor the equipment to ensure that it is performing as expected, and that the outlined design objectives and business case performance metrics are being met

- Project closure

When to Automate Your Warehouse

So, when should you automate your warehouse? By the time most businesses realize they need to invest in warehouse automation or increase their current use of business automation, it’s likely pain is already being realized. See best practices below to learn the importance of planning ahead.

Best Practices of Warehouse Automation

1. Plan

The timeline to implement warehouse automation can vary from a few months up to 2 years for large projects.

2. Develop a Strategic Roadmap

Your strategic planning should integrate an automation roadmap for your facility and network.

3. Work With a Strong Partner

Signs that you’ve identified the right partner:

- The most competent partners are going to have significant engineering expertise in addition to supply chain and operational know how.

- The design team will develop designs using first principles, not by analogy (i.e., deploying their product portfolio or whatever worked for the last customer).

- They will hold themselves accountable to the entire project lifecycle from design, implementation, and acceptance.

- They will likely be supplier agnostic and not have exclusive relationships in the market.

- They will be competent project managers and risk managers.

4. Evaluate Multiple Suppliers

Individuals and organizations alike have tastes and preferences, even for warehouse automation. Often, there can be a strong predisposition to use a particular supplier or technology. It is best to consider multiple options and evaluate those options using a methodology that is analytically robust and yields a pragmatic result.

5. Establish a project structure

For all projects, but particularly larger capital projects and complicated retrofits, it’s important to define the overall project for each workstream involved. Typically, a project would have up to 9 workstreams, each with a dedicated lead identified to ensure the success of that workstream and would report up to a Program Management Office or “PMO”. These workstreams are:

- Building / real estate

- Design and material handling system

- WMS and IT systems

- Operational readiness

- Facility readiness

- HR and “people” readiness

- Testing and acceptance

- Change management

- Finance

Each of these workstreams should report up to the PMO where the project owner holds responsibility for the overall program.

Other Considerations for Warehouse Automation & Design

- Variability – automation costs less and performs more reliably with low variability. As variability increases, so does the level of sophistication required to support, and higher costs are likely.

- Interoperability – warehouse automation should integrate with other physical and digital systems around it. Without a well-integrated system, operating potential will be hindered.

- Resiliency – warehouse automation should be able to recover quickly from downtime events, and not be disrupted too easily with changing business conditions.

- Scalability – systems that can be phased in over time will ultimately provide more flexibility to companies looking to right size their investments and avoid “building the church for Easter Sunday.”

- Stakeholder alignment – all key stakeholders need to be aligned to ensure successful deployment of warehouse automation including Operations, IT, Maintenance, and your Executive Leadership.

- Compliance – warehouse automation must comply with numerous local, state, and federal regulations and safety requirements. This includes life safety, fire safety, structural, and other regulatory matters.

- Governance – warehouse automation can often be the largest supply chain investment companies make. Project governance is important to ensure alignment, and maintain financial controls, reporting, and risk management.

- Measures – how will you measure performance? How will you define success? Having appropriate measures is key to knowing you’re on track and to know what success looks like.

- Obsolescence – all things eventually come to an end, including warehouse automation. It’s important to understand lifetime value and replacement plans for all warehouse automation.

The Bottom Line

Warehouse automation is fundamentally changing how distribution centers and warehouses operate. The financial justification for warehouse automation is becoming increasingly clearer and more compelling. Companies that work with the right partner to develop an automation strategy and integrate warehouse automation will have superior operating efficiency and potential over time.

You may also like

These related articles