Order fulfillment is a critical aspect of any business that sells and ships physical products to its customers. It involves the entire fulfillment process from receiving an order, picking the product from inventory, packing, and shipping the order to the customer on time. In this article, we will dive into the world of order fulfillment, discussing its importance, different types, process, challenges faced by businesses, what to look for in a fulfillment service, and tips for improving your order fulfillment process.

What is Order Fulfillment?

Order fulfillment encompasses the process of receiving, processing, and delivering orders to customers. This process includes the product’s entire journey, from a customer placing an order to receiving their product in a timely manner. Order fulfillment also includes the process of product returns. In order to fulfill customer expectations, a business must be able to receive the order, pick the correct items from their storage location, pack the order in shippable containers, and then ship the final assembled order to the customer. An efficient order fulfillment strategy will enable you to efficiently deliver the right products to the right customer at the right time.

Why Efficient Order Fulfillment Matters

Since order fulfillment is a customer’s primary interaction with a company, it has a direct and meaningful impact on customer satisfaction, experience, loyalty, and lifetime value. Efficient order fulfillment effectively impacts all future sales. The customer’s lasting impression of the company, including the probability of repeat orders, will likely be based on the results of the order fulfillment process and the overall customer experience. Similarly, a good order fulfillment process is important for the company responsible for fulfilling the order, as it contributes to significant operating costs, including labor, shipping, inventory, and real estate costs. These costs can be reduced by designing and implementing a more efficient order fulfillment process.

Types of Order Fulfillment

There are several types of order fulfillment, each catering to different applications and needs. Some companies manage their order fulfillment internally, while others choose to outsource to third-party services. Regardless of the chosen fulfillment model, the goal remains the same: distribute products to customers. However, the details of this distribution process can vary depending on the type of order fulfillment processes deployed. This article seeks to explore some of the variations of order fulfillment and highlight the key differences between the different types of fulfillments available.

In-House Order Fulfillment

In-house fulfillment involves a business fulfilling orders internally. The business maintains a warehouse or storage facility to hold products, and employs workers who pick, pack, and ship those products. For businesses that have a relatively small number of orders who can handle the volume with their existing resources, it is a common practice to fulfill those orders in this method. It allows companies to have complete control over their order fulfillment process and makes it easier to make necessary adjustments as the business changes.

Bigger facilities may still fulfill orders internally, but they likely rely on advanced technology, warehouse management systems, and warehouse automation to pick, pack, and sort products – instead of human operators exclusively. Warehouse automation such as conveyor and sortation systems, light directed picking, packaging automation, and automated print and apply allow companies to flow much higher volumes of orders, while maintaining control over the order fulfillment process. However, warehouse automation can be expensive both in initial capital and to maintain, especially for a rapidly-scaling business. In these cases, businesses will often outsource their order fulfillment to a third party.

Check out this in-depth article on warehouse automation for additional information.

External Order Fulfillment

In contrast to internal order fulfillment, companies may opt to fulfill their orders through external parties. When businesses experience rapid growth or experience high volume of orders that exceeds their internal capacity, it is common for them to engage in the services of external order fulfillment companies. Additionally, certain product categories could be advantageous to have externally fulfilled for cost or efficiency reasons. Bulk, heavy, and irregular shaped products are often segregated in the fulfillment process due to their unique handling requirements and are often externally fulfilled. There are two main types of external fulfillment: third party fulfillment and dropshipping.

Third-Party Order Fulfillment (3PL)

Third-party fulfillment, often referred to as a "3PL" (third-party logistics company), involves partnering with an external company specialized in order fulfillment to handle the process on behalf of another company. In this model, the product is shipped from the manufacturer to the 3PL, which then stores the inventory. When a customer places an order, the 3PL is responsible for picking, packing, and shipping the products to the customer.

Third-party fulfillment is a beneficial option for businesses that want to concentrate on their core competencies and refine their products. It is particularly advantageous for companies experiencing rapid growth and requiring quick scalability of their order fulfillment operations, such as those with seasonal businesses and high order volumes within a short timeframe. Another advantage is the ability to localize products by stocking them in 3PL warehouses near customers, resulting in reduced shipping time and costs.

However, there are some drawbacks to third-party fulfillment. Companies relinquish a degree of control over the fulfillment process, as 3PL providers may make mistakes such as shipping the wrong product, delayed shipments, or delivering to the wrong address, with the original company being held accountable by the customer. Additionally, the packaging and unboxing experience may not be fully customizable since 3PLs often serve multiple companies, limiting packaging customization options.

Overall, third-party fulfillment offers benefits in terms of focus, scalability, and cost reduction, but it also involves trade-offs in terms of control and customization of the fulfillment process.

Dropshipping

Dropshipping is different from third-party fulfillment or in-house fulfillment because the business does not stock or, in some cases, even own the product they sell. Instead, when an order is placed, the business purchases the product directly from the original manufacturer or another distributor and has it shipped directly to the customer on behalf of the business. This model is typically a good option for small or new businesses that do not yet have the resources to handle order fulfillment or for businesses dealing with particularly large bulk products. It minimizes the initial capital costs since there is no need to purchase inventory until after the order is placed.

The downsides of dropshipping are shared with third-party fulfillment in that the company has little to no control over their order fulfillment process. This can expose the company to risks related to product quality, unboxing experience, and delays beyond the company’s control.

The Order Fulfillment Process

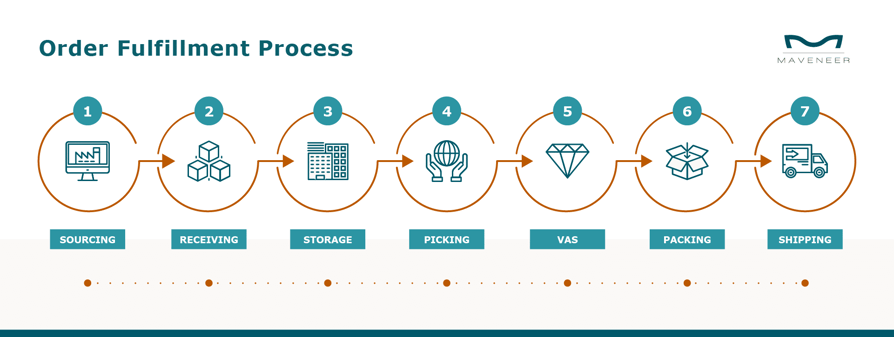

Figure 1. Order fulfillment encompasses every part of the flow from sourcing a product to shipping to the customer.

Order fulfillment involves a streamlined process consisting of seven key steps:

1. Sourcing

The process commences with sourcing goods from manufacturers or suppliers, whether domestically or internationally. Businesses purchase the goods and arrange for their shipment to their warehouse, distribution center, or 3PL vendor.

2. Receiving

Upon arrival at the warehouse or distribution center, the goods are received and inspected. This critical stage ensures proper quality checks, quantity verification, and accurate storage, enabling management systems like Warehouse Management Systems (WMS) to track available inventory.

3. Storage

Efficient storage is essential for organized and easily retrievable products. The selection of appropriate storage solutions, such as shelving, racking, or automated storage and retrieval systems (ASRS), depends on factors like SKU velocity, density requirements, shelf life, product size, and packaging type.

4. Picking

Once orders are received, the picking process begins. Software, like Warehouse Execution Systems (WES), optimizes the picking process, minimizing touches, and guiding pickers along efficient routes. Automation options vary based on order profiles and the SKU base of the business.

5. Packing

After picking, the ordered items are consolidated and packed into shipping containers. These containers can range from corrugated boxes, polyurethane bags, envelopes, cold seal packages, totes, or even pallets for larger volumes. In retail fulfillment, entire trailers may be loaded with products for delivery to stores.

6. Value-Added Services (VAS)

Certain orders may require specialized services, known as value-added services (VAS). Examples include apparel tagging, book labeling, hazardous material regulatory labeling, or customized packaging for high-value or gift items.

7. Shipping

Shipping is the final step in the order fulfillment process. Businesses can choose from various carriers and service levels based on their geographic reach. Automated shipping systems optimize cost by selecting the most economical shipping option using packaged dimensions, resulting in significant savings.

By effectively managing these seven steps, businesses can enhance their order fulfillment processes, ensure customer satisfaction, and drive overall operational efficiency.

Challenges of Order Fulfillment

The process, described in detail above, is simple in concept, but is mastered by fewer companies than you might expect. Each step of the process has its unique opportunity for efficiency as well as potential points of failure. Below common challenges that any business faces with order fulfillment, along with a few solutions on how to succeed in the face of this simple, yet dynamic, process.

Inventory Management

- Challenge: Forecasting and maintaining the appropriate amount of inventory for each SKU.

- Solution: Implement warehouse management system or a basic location management system. Frequently audit locations and implement quality control measures with suppliers.

Order Accuracy

- Challenge: Ensuring every order matches exactly what the customer ordered

- Solution: Utilize location management systems and scan the location, the item, and the order container during the picking process.

Delivery Time

- Challenge: Meeting customer expectations and service level requirements for delivery time after the order is placed.

- Solution: Optimize the order fulfillment process and negotiate a better shipping time frame with common carriers

7 Tips for Improving Your Order Fulfillment Service

1. Leverage Your Data for Better Decision Making

Understanding your historical and real time data can greatly impact the efficiency and outcomes of your fulfillment process. Historical data can help you understand how well or poorly you’ve been operating over time. It can also help you influence future state requirements for future projects when a growth forecast is applied to the baseline data. Additionally, Key Performance Indicators, or KPIs, can be used to set goals to track the efficiency and effectiveness of your order fulfillment process. KPIs can help you identify areas for improvement, inefficient processes, and redundancies that might be holding your process back.

2. Invest in Warehouse Automation

Warehouse automation encompasses various form factors and applications, offering a wide range of benefits across order fulfillment processes. These include conveyor sortation systems, AS/RS, Goods to Person, and other categories. The industry provides diverse technological offerings that can improve nearly every aspect of order fulfillment. However, it's crucial to exercise caution and not assume that all technologies guarantee a high return on investment. When considering warehouse automation, it's important to understand that it thrives on throughput to achieve a positive return on investment. High throughput operations don't automatically justify the highest levels of warehouse automation. Conversely, lower throughput operations can still benefit from scalable levels of warehouse automation that can grow with the business over time. Therefore, a careful analysis and consideration of automation options should be undertaken before investing in or selecting a service provider. By approaching warehouse automation with a discerning mindset and conducting thorough analysis, businesses can make informed decisions, ensuring that the chosen automation solutions align with their specific needs and have the potential to generate a positive return on investment.

3. Start with Picking

If you're not sure where to start optimizing your warehouse operations, begin with order picking. Why? Order picking alone typically accounts for 40-60% of all direct labor in a warehouse, making it a crucial area for improvement. By focusing on incremental enhancements to the pick process, you can effectively reduce operating costs and unlock significant efficiency gains. Optimizing order picking can lead to improved accuracy, faster order processing times, and enhanced resource utilization. Through strategies like batch picking or zone picking, businesses can minimize travel distances and maximize productivity. Prioritizing the optimization of order picking is a strategic approach that can yield substantial cost savings and operational improvements throughout the warehouse.

4. Provide Excellent Customer Service

Delivering exceptional customer service is an invaluable asset for any company. By being transparent with customers regarding inventory availability, shipping delays, and any changes, you cultivate trust that fosters customer loyalty. Maintain regular communication throughout the order fulfillment process, keeping customers informed about order status and promptly addressing their inquiries or concerns. In addition to cultivating a devoted customer base, providing outstanding customer service minimizes the likelihood of negative reviews or feedback and promotes repeat orders, ensuring ongoing business success.

5. Implement Quality Control Processes

Implementing effective quality control processes is crucial for ensuring that your products are shipped in optimal condition, thereby reducing returns and exchanges. By establishing clear product quality standards and implementing standard operating procedures (SOP), you can maintain a high-quality output throughout the order fulfillment process. This is particularly important when dealing with operations beyond the direct purview of your business. Incorporating quality control measures such as spot checks or comprehensive reviews enables you to identify and address any issues with your products prior to shipment, minimizing the likelihood of returns and exchanges while incurring minimal upfront costs. Through a proactive approach to quality control, you can enhance customer satisfaction and uphold the reputation of your brand.

6. Cultivate a Culture of Excellence

In the fast-paced world of order fulfillment, cultivating a culture of excellence is paramount to achieving operational success. A strong and positive culture instills a shared sense of purpose, teamwork, and commitment among the employees involved in the fulfillment process. It fosters an environment where attention to detail, accuracy, and efficiency are valued and prioritized. By fostering a culture that emphasizes continuous improvement, open communication, and collaboration, businesses can drive employee engagement and motivation, leading to increased productivity and reduced errors. A positive culture also promotes innovation and problem-solving, empowering employees to find creative solutions and adapt to evolving customer needs. Moreover, a culture of excellence in order fulfillment extends beyond the internal operations—it reflects in the quality of customer service, satisfaction, and ultimately, customer loyalty. Nurturing a culture of excellence within the order fulfillment operation sets the foundation for long-term success and growth in the competitive e-commerce landscape.

7. Work With a Strong Solution Design Partner

Partnering with a strong solution design partner is crucial when developing the optimal order fulfillment process for your operation. If you find yourself uncertain about where to begin or lack the expertise to design the most effective solution, seeking out a competent solution design partner is highly recommended. Here are key indicators that you have identified a robust partner capable of assisting with your order fulfillment:

- Comprehensive Expertise: The most competent partners possess substantial engineering expertise, complemented by in-depth knowledge of supply chain, warehouse automation, and operations.

- First Principles Approach: The design team will develop solutions based on first principles rather than relying solely on analogies or pre-existing product portfolios, ensuring a tailored approach for your specific needs.

- Accountability throughout the Project Lifecycle: A strong partner takes responsibility for the entire project lifecycle, including design, implementation, and acceptance, ensuring a comprehensive and seamless process.

- Supplier Agnosticism: They will maintain an unbiased stance towards warehouse automation and key technologies like WMS, avoiding exclusive relationships and enabling the selection of the most suitable solutions for your requirements.

- Proficient Project and Risk Management: Competent partners excel in project and risk management, facilitating the execution of improvements to your order fulfillment process with efficiency and effectiveness.

By working closely with a strong solution design partner possessing these qualities, you can confidently navigate the complexities of order fulfillment, leverage their expertise, and implement a customized solution that optimizes your operational efficiency.

The Bottom Line

Order fulfillment plays a vital role in the success of businesses selling physical products. Regardless of whether you opt for in-house fulfillment, third-party providers, or a dropshipping model, a thorough comprehension of the process and its challenges is crucial. By selecting the appropriate fulfillment service, adhering to best practices, and continuously optimizing the order fulfillment process, you can cultivate a remarkable customer experience that fosters loyalty, drives repeat business, and unlocks further sales opportunities. With a focus on efficient and reliable order fulfillment, you can set your business apart in the competitive marketplace and achieve long-term growth and customer satisfaction.

You may also like

These related articles